Laser Cutting Machine X-axis

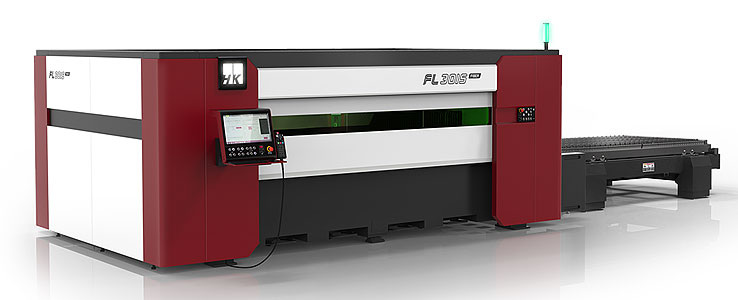

GSS Machinery highspeed CO2 lazer machines come in a range of configurations to match your budget and process needs.

Send your design for the laser. In the print driver, you can select the parameters to be used or a preset from GSS Machinery.